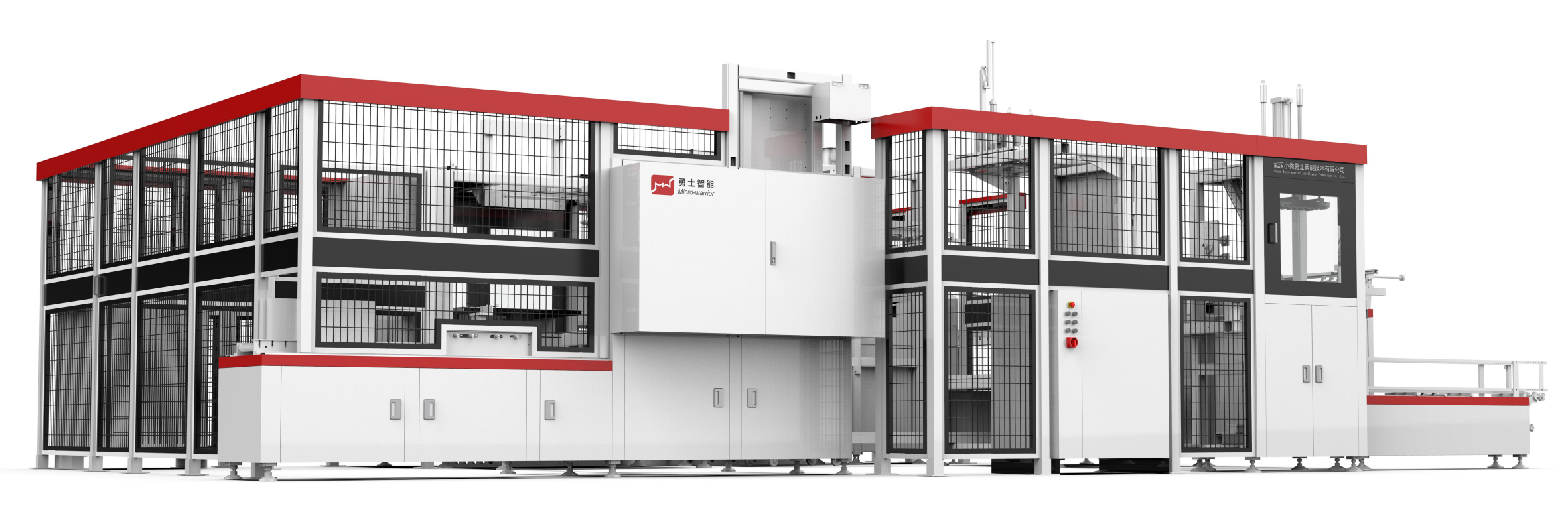

COS for OPZV/OPZS battery is suitable for the production of tubular lead-acid battery. It is a high performance and intelligent equipment for casting and welding of lead-acid battery plate group strap and end pole.

One COS mold out of four: uniplate group thickness 50~150mm, single cycle 90 seconds, 1500pcs /shift;

One COS mold out of two: unipolar group thickness 100~280mm, single cycle 90 seconds, 720pcs / shift.

Technical Instruction

1. The plate group into the jig station: the manipulator gripper clamp 2 to 4 groups of horizontally placed 2V tubular plate group, into the horizontal horizontal jig.

2. Plate group lug neat and fixture locking station: plate group vertical, with the bottom of the plate as the total height of the plate group neat benchmark, front and back side plate neat, lug neat after the pole group clamping.

3. Fixture reverse station: reverse the fixture, the pole ear direction down.

4. Cutting brush lug station: first cut the total height of the lug, the length of the lug can be 0~10mm.

5. Lug dipped tin station: plate group lug brush flux, dipped tin, etc.

6. Casting and welding mold station: lug casting and welding strap; The common mode of different length of bus is realized by insert block. Independent control of positive and negative temperature.

7. Lead fur processing station: cutting brush to remove the lead fur.

8. Fixture rotation return station: to achieve the lug direction up.

9. Into slot station: When the plate group is pushed into the battery slot, the uniplate group is supported by the full roller when sliding outside the slot, to ensure that the porous mesh can smoothly enter the battery slot.

10. Battery output roller table: the battery output after entering the slot.

11. Battery slot feeding station: battery slot feeding positioning.

12. Jig rotation station: empty jig rotation to the starting station.

13. Fixture loosening station: fixture overtime open.

14. Fixture automatic conversion positioning: initial fixture positioning.

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

©2024. WUHAN WARRIOR . All Rights Reserved.